Sectors

- Precision Tooling

Precision Tooling

With 35 years of experience in manufacturing high-precision molds, we have a set of finished mold design standards, we know how to manufacture stable, efficient, durable high-quality molds for applications in the automotive industry, medical devices, personal care and packaging.

Hongrita's commitment to technological excellence allows it to stay at the forefront of manufacturing innovations. The company continuously invests in research and development to adopt cutting-edge technologies, which enhances its ability to produce high-quality precision plastic components and products.

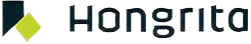

Multi-Component Molding

Multi-Component Molding: Hongrita has a deep understanding of multi-component molding, which involves combining different materials or colors in a single mold to create complex and multi-functional parts. This expertise allows them to offer innovative and customizable solutions to their customers.

Multi-Component Molding

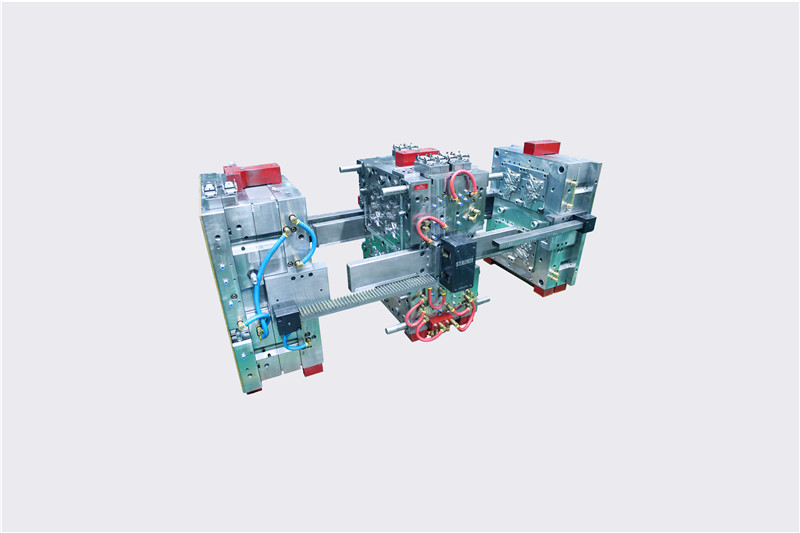

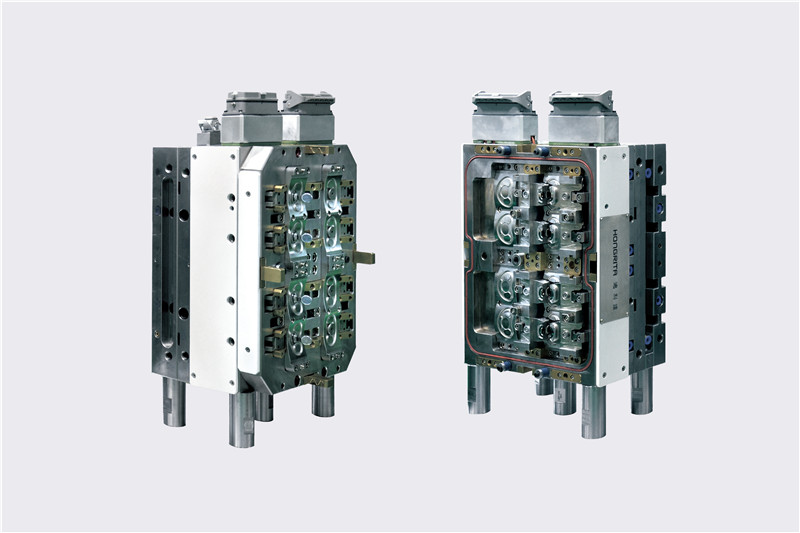

Multi-Cavity Mold

The multi-cavity moulds manufactured by Hongrita can meet the high standard requirements of customer customization.The modular structure of the mold means a high degree of flexibility. In addition, the interchangeable mold inserts enable the basic mold to be used in a variety of products. Innovative cooling technology and selected coatings ensure minimum cycle times and long service life.

Multi-Cavity Mold

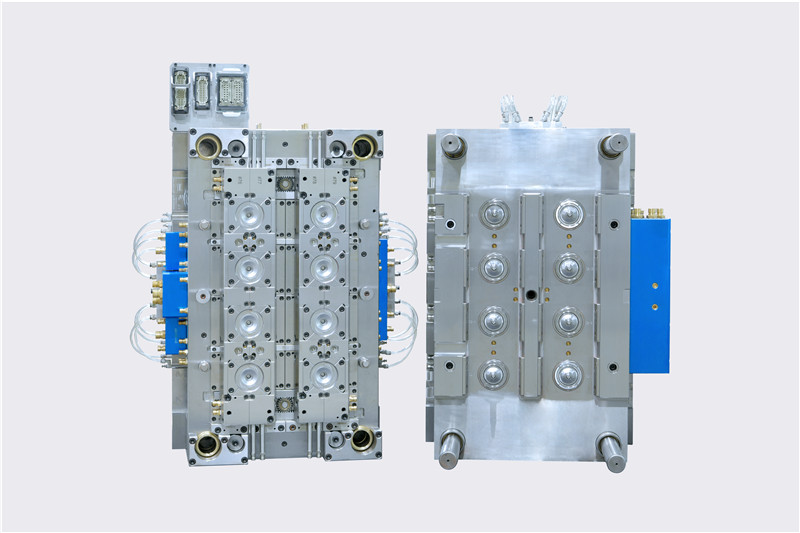

LSR Mold

Hongrita LSR molds with a valve cold runner system were developed in-house. It can be used to create very complex LSR parts with much finer details and tighter tolerance. Hongrita can even master high cavitation LSR & 2-Component LSR/LSR or LSR/Thermoplastics tooling technologies, benefiting industries demanding high quality silicone parts and high efficiency silicone molding.