CORE COMPETENCES

Core Competences

Hongrita's core competences form the foundation of the competitive edge at plastic industry:

- Technology Excellence

- LSR (Liquid Silicone Rubber) Molding

- Multi-Component Molding

- ISBM (Injection Stretch-Blow Molding)

- High Performance Tooling Solutions

- Smart Manufacturing

Hongrita's core competences in ISBM, LSR molding, multi-component molding, tooling, and smart manufacturing collectively strengthen its position as a leading provider of precision plastic components and products. These competences allow Hongrita to deliver innovative and tailor-made solutions to diverse industries, including medical, healthcare, automotive, and rigid packaging, while continuously pursuing technological excellence and sustainable business management practices.

Laboratory

-

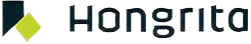

Optical Measurements

- High-precision measurement

- Non-contact measurement

- Production efficiency improvement

- Quality control and improvement

- Research and innovation in new materials

-

Physical Measurements

- Quality control

- Process optimization

- Fault diagnosis

- Resource conservation

-

Environmental Testing

- Regulatory compliance

- Innovation opportunities

- Sustainability and environmental protection

-

Reliability Testing

- Product quality validation

- Defect prevention

- Cost savings

- Increased customer satisfaction

- Continuous improvement

-

Baby Care Product Testing

- Product Safety assurance

- Quality control

- Innovation and R&D

-

Microbiological Laboratory

- Product hygiene and safety

- Production process control

- Compliance with regulations and standards

- Quality assurance

- Health certification and trust

-

Physical and Chemical Laboratory

- Raw material control

- Production process optimization

- Product functional test

- Fault analysis and improvement

- New product R&D

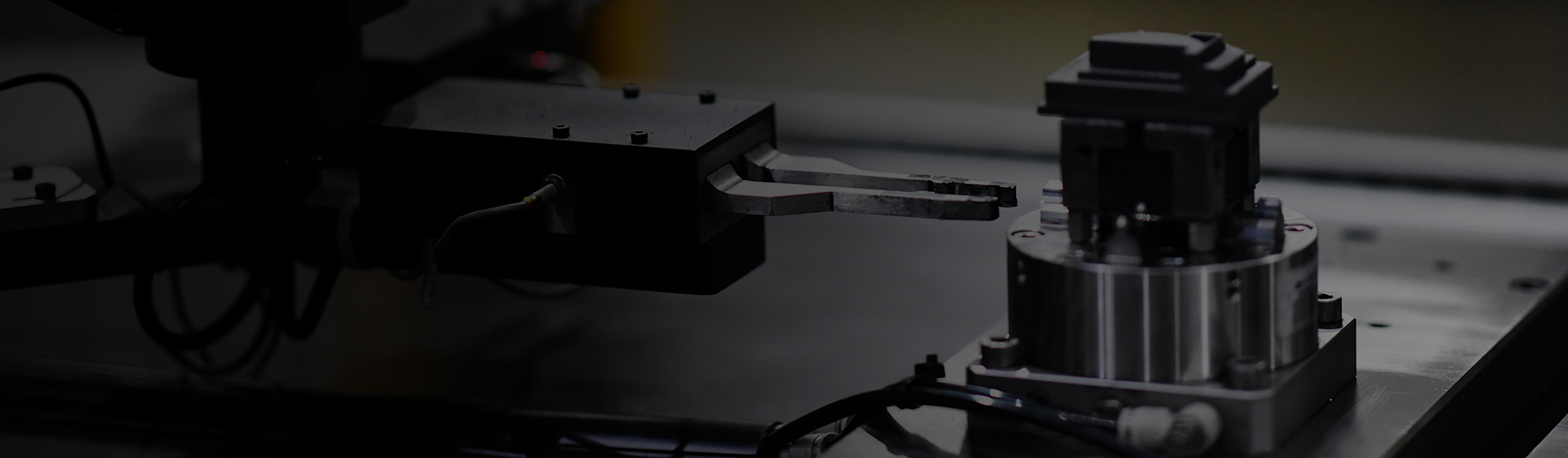

Smart manufacturing

The application of smart systems has enabled Hongrita to achieve better production automation, digital management, and AI decision-making, thereby enhancing the factory's level of intelligence, optimizing enterprise operational efficiency, and quality management, and strengthening the company's competitiveness in the industry.